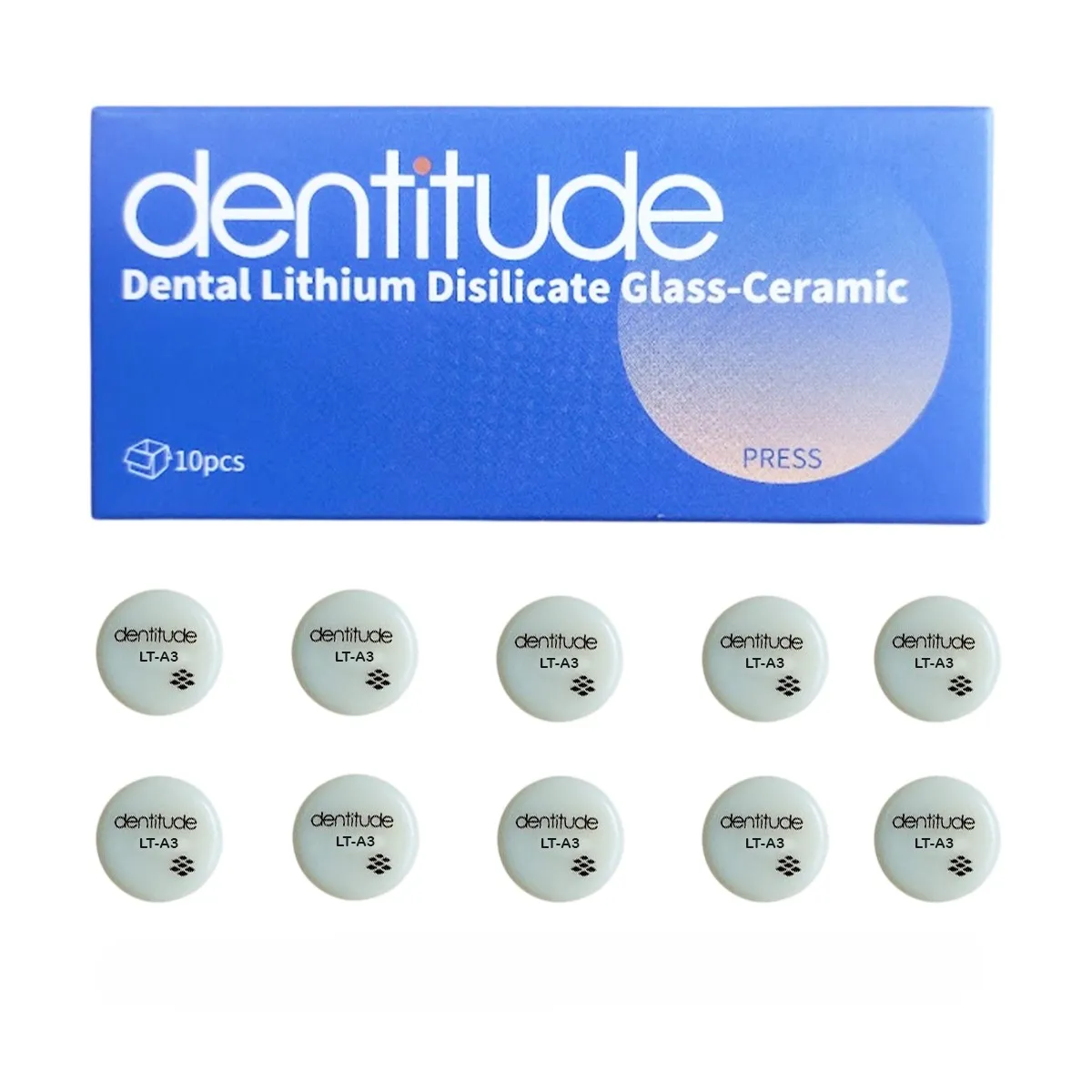

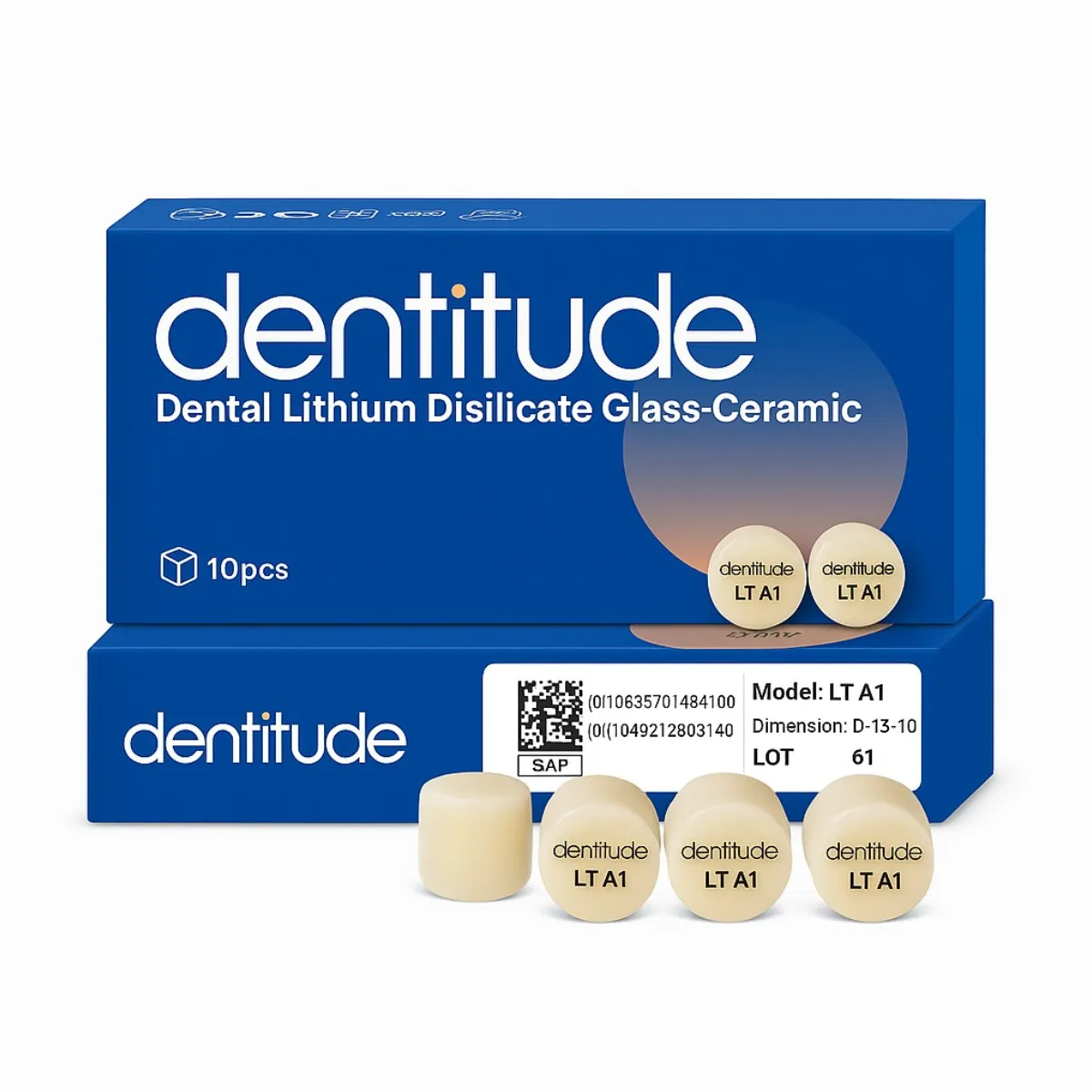

The Ceramic Blocks category on Dentalkart features a curated range of high-performance materials used for fabricating esthetic, durable, and biocompatible dental restorations. These blocks are essential for CAD/CAM milling systems and are ideal for creating crowns, bridges, inlays, onlays, and veneers with high precision and superior aesthetics.

This category includes lithium disilicate blocks, leucite-reinforced glass ceramics, and multilayered systems from top brands such as Upcera, Aidite, and Noritake, known for their shade fidelity, machinability, and strength. Available in various translucencies, shades, and block sizes, these products cater to diverse clinical and lab needs, from monolithic restorations to layering ceramics.

Clinical Importance of Ceramic Blocks

Ceramic blocks play a pivotal role in restorative dentistry by enabling the fabrication of lifelike restorations that mimic natural enamel in translucency, color, and gloss. They combine mechanical strength with exceptional aesthetic properties, offering:

-

High flexural strength and fracture resistance

-

Superior polishability and optical integration

-

Biocompatibility and longevity

-

Compatibility with CAD/CAM workflows for chairside or lab milling

These attributes make ceramic blocks suitable for anterior esthetic zones as well as posterior functional areas.

Category Highlights

The Ceramic Blocks section on Dentalkart is designed to meet the demands of both dental laboratories and chairside CAD/CAM systems. Some key subtypes available include:

-

Lithium Disilicate Blocks – Ideal for high-strength, lifelike anterior and posterior restorations (e.g., Upcera UP Press LT, Aidite Cameo, Upcera CAD LT)

-

Glass Ceramic Ingots – Designed for pressable systems with enhanced strength and natural translucency (e.g., Upcera Press Ingots)

-

Multilayer Blocks – Offer natural gradient shading across dentin to enamel for esthetic excellence

-

Noritake EX-3 – For ceramic layering in combination with zirconia or metal frameworks

-

CAD-compatible blocks – Suitable for popular CAD/CAM systems with optimal cutting properties

Why Material Selection Matters

Choosing the right ceramic block affects not just the aesthetic outcome, but also the long-term durability and patient satisfaction. Important considerations include:

-

Shade match & layering requirements

-

Strength needs (posterior vs anterior)

-

Compatibility with the milling unit or press system

-

Translucency levels based on tooth position and patient age

-

Bonding or cementation preferences

Dentalkart helps streamline this decision-making process by offering detailed product specs, reliable sourcing, and brand-backed quality assurance.

Trusted Brands on Dentalkart

Our ceramic blocks are sourced from globally reputed manufacturers like:

-

Upcera – Known for high-strength lithium disilicate and multilayer zirconia solutions

-

Aidite – Offers superior esthetics and polishability with CAD/CAM blocks

-

Noritake – A leader in layering ceramics for long-term clinical success

Storage & Handling Guidelines

-

Store in a cool, dry place, free from humidity and direct sunlight

-

Avoid dropping or mechanical damage before milling

-

Follow manufacturer’s guidelines for pre-treatment (e.g., cleaning, drying)

-

Use compatible burs and software settings for precise results

-

Wear protective gear during milling and polishing

Ideal for Labs and Chairside Dentistry

Whether you're a dental technician, prosthodontist, or general dentist equipped with a CAD/CAM unit, the Ceramic Blocks category ensures you have access to proven, high-quality materials for all restorative demands. Clinics benefit from consistent esthetic outcomes, and labs enjoy efficiency with minimal rework.

FAQs – Ceramic Blocks in Dentistry

1. What types of restorations can be made using ceramic blocks?

Ceramic blocks are primarily used for fabricating crowns, bridges, veneers, inlays, and onlays. Lithium disilicate and glass ceramics are especially suitable for anterior esthetics and posterior strength.

2. Are these ceramic blocks compatible with all milling machines?

Most blocks are compatible with major CAD/CAM systems, but it is important to check size, connection type (e.g., C14, B32), and software compatibility before purchasing.

3. What is the difference between CAD blocks and pressable ingots?

CAD blocks are milled using a digital workflow, suitable for chairside or lab-based CAD/CAM units. Pressable ingots are used in heat-press systems and require waxing and pressing, preferred for layered or more artistic restorations.